Fail to prepare – prepare to fail!

Nick Coombes explains how even today’s sophisticated technology can be nullified

Nick Coombes explains how even today’s sophisticated technology can be nullified

In the forty years since I joined the printing industry, just before Drupa 1977, the world of print has changed almost beyond recognition – in fact media in general is completely unrecognisable, such is the march of time and the advances in technology it brings. Shortly before I started, letterpress had given way to litho, and flexo, to many, was a ‘dark art’ that fell far behind in quality and performance.

Today, HD-flexo quality is second to none and anyone choosing to dispute that needs only to look at the vast volumes of eye-catching print, especially package print, that is produced and consumed by the global market each day. While offset might be the preferred choice of ‘fine art’, modern day flexo is what keeps the presses running and the money changing hands. From a crude process to a highly controllable precision process in one generation is no mean feat, but press technology alone could not have achieved this without a raft of improvements from what I shall call ‘ancillary suppliers’.

The confines of this article does not allow for an overview of all that has happened to improve flexo print quality, so I shall limit my discussion to the fundamental issue of surface treatment – or what makes the ink stick! It was in the early post-war years of the 1950s that the problem first came to light in a big way, when the new ‘plastic’ type substrates were launched onto the market and into a world that was just beginning to understand the term ‘consumerism’. The problem was that, unlike natural fibres such as paper and board, into which ink could be partially absorbed, this new material was proving to be resolute in its unwillingness to accept and keep ink on its surface.

It was a chance conversation among friends that provided the solution, which from humble beginnings has grown to become the norm for many substrates and a global standard for the industry. The problem of course was surface tension, and the solution invented by a Danish radio-phonics engineer called Verner Eisby, was what we now know as ‘corona treatment’. To appreciate the value of the process, it is important to understand the science behind it.

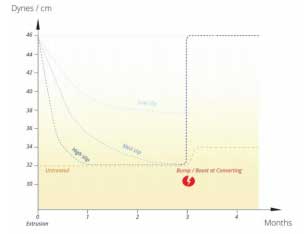

Any man-made synthetic material contains long homogeneous molecule chains that form a strong and uniform product. These chains join other long chains, leaving only a few open chain ends, and therefore only a small number of surface bonding points, and this is where the problem of low adhesion and what is known as ‘wettability’ occurs. Wettability is the ratio between the surface energies of the liquid ink and the solid substrate. In general, a material can be wetted if its surface energy, measured in dyne/cm, is greater than the surface energy of the liquid. If it’s the other way around, there will be adhesion problems.

So, how does corona work? The high frequency discharge during the corona process increases the wettability by rupturing the long chains and creating more open ends and free valences. The ozone in the electrical charge is accelerated onto the surface, which in turn forms new carbonyl groups with a higher surface energy. The result is a higher dyne level, and better adhesion. Importantly, this surface treatment does not reduce or change the strength of the substrate, nor does it change its appearance. In fact, corona treatment affects only the top molecule chains that are 0.00001-micron thick, and works equally well on film and foil that requires printing, laminating or coating.

The effectiveness of corona treatment depends on the specific material being used. Materials have different characteristics and different amounts of slip and additives, which will determine the effect of the corona treatment. But, there are no limits to the materials that can be corona treated, although the required intensity of the treatment, measured in watt/min/m2, may vary significantly.

Over time, the obtained dyne level can decrease and it may be necessary to treat the material again just before use. When a material contains slip, the dyne level falls faster, and thicker and older film stocks are more difficult to treat as slip agents may have migrated to the surface. Storage conditions and temperature can also affect the loss of corona treatment. Generally speaking, the higher the amount of slip, the quicker it is likely to decay. It has also been proven that some films with very high slip additives, say over 1200 ppm, can be totally resistant to printing just 24 hours after treatment, and it may be necessary to process this film immediately after treatment, or boost the treatment inline with the printer.

Material that has not been treated under extrusion can also be difficult to treat afterwards. Pioneers of the process, Vetaphone, recommend treating film just after extrusion, and then using a refreshment treatment, if necessary, just before the liquid or media is supplied to the surface in the converting process. In every case, it is recommended to check the surface energy of each substrate before processing. This is done using a dyne pen before and after treatment. If the level is insufficient, the corona treater should be adjusted to a higher setting, and the dyne test repeated until the required adhesion is achieved. Other factors to consider are the web width, speed, and the number of sides to be treated. If any of these are changed, then the setting of the corona treater must be adjusted accordingly.

If the science of corona treatment is lost on many, the realities of its effects and the benefits it brings are all too obvious. If I may draw an analogy to highlight its importance, please consider how well the best F1 racing cars would perform if they were using low grade fuel. So too with today’s highly sophisticated printing presses, the quality coming out is dependent on the quality going in. And sometimes, the seemingly insignificant elements are the most important.

By Nick Coombes

Nick Coombes has 40 years’ experience in the printing industry. He is editorial consultant to international print magazines including Folding Carton Industry, Labels & Labeling, and Narrow Web Tech, and marketing adviser to a number of leading technology manufacturers.